INDUSTRIAL

SEALS

At BOUWTECH BV, we proudly serve as the representative in the Benelux region for TECHNOSEAL SERVICES SRL ROMANIA which is specialized in the production of non-asbestos soft gaskets.

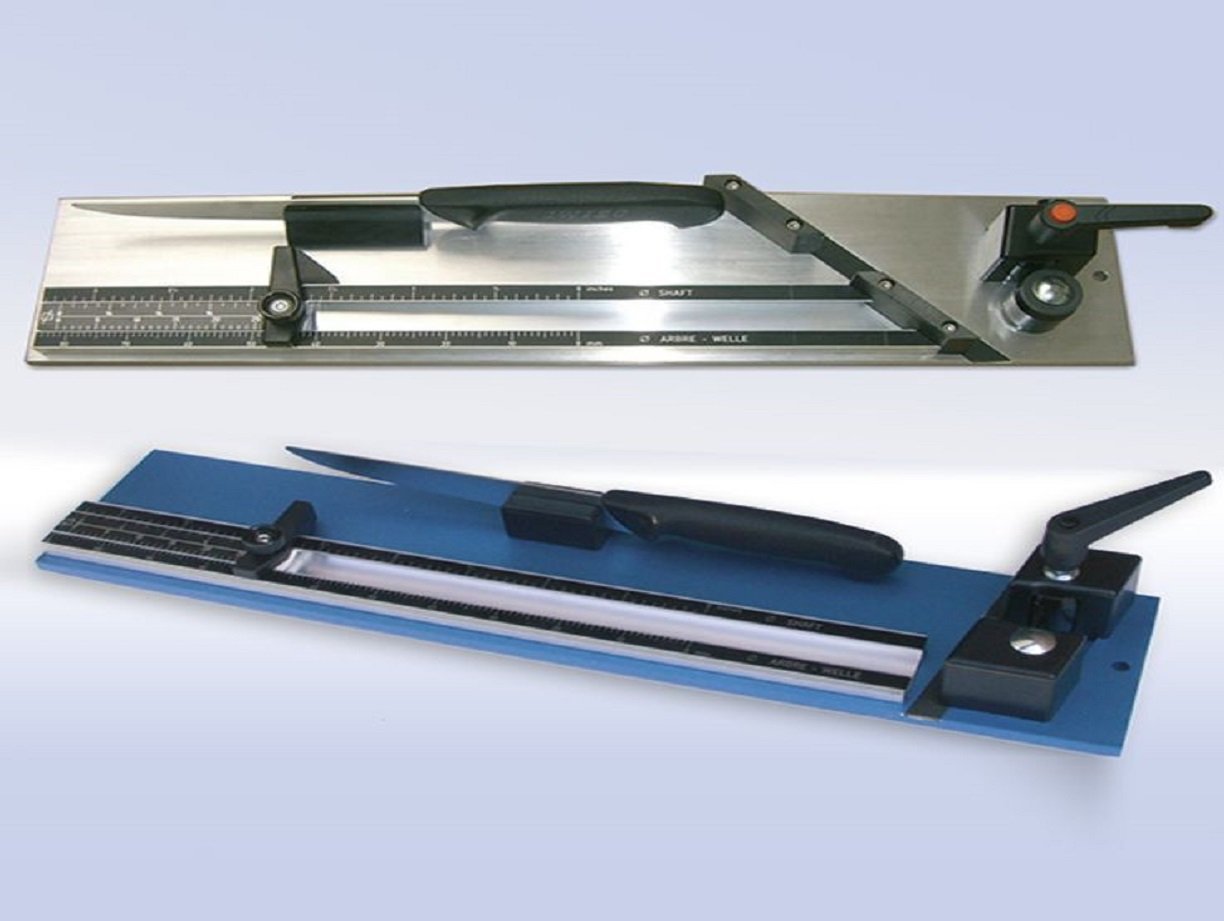

Using a latest technology cutting machine with numerical control we can produce according to the standards (SR EN, DIN, ANSI, JIS) or nonstandard dimensions of any shape or size according to client drawings and requirements.

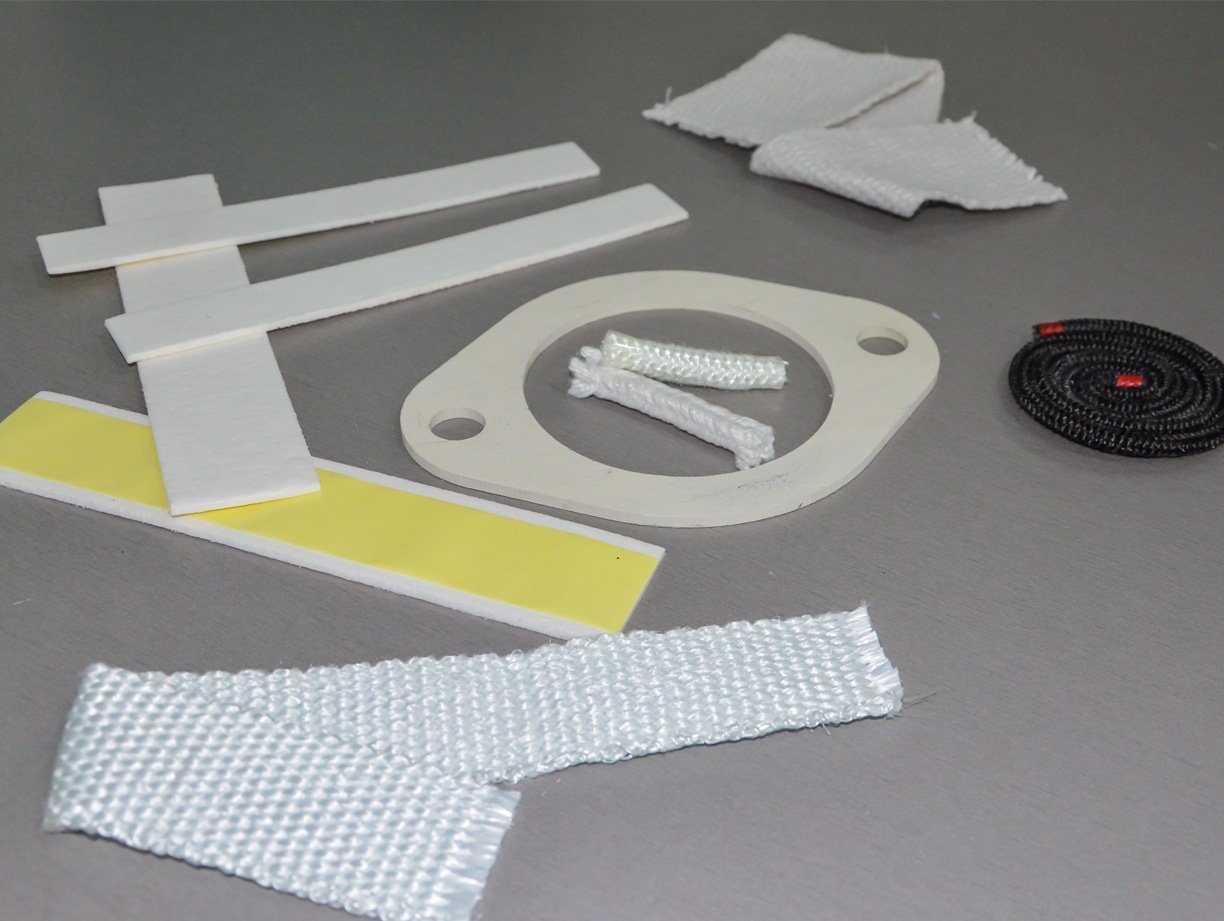

The product range includes sheets seals for dynamic equipment, braided packings for pumps and valves, mono or multidirectional expanded PTFE products, sintered PTFE products such as: sheets, bars, sleeves, processed parts, rubber products, plastics, heat-resistant materials.

In the same time, we provide our customers technical support in choosing materials for specified applications and assistance when installing sealing materials.

We offer a range of complementary services consisting of:

- Technical evaluation of the dynamic equipment on which the seals will be installed;

- Choosing the technical solution that meet the requirements of the application;

- Technical assistance for installation and commissioning;

- Cutting soft non-asbestos gaskets, standard (EN, DIN, ANSI, JIS) or customer-specified.

- In-house or on beneficiary's premises staff training.

Our product range encompasses a variety of high-quality sealing solutions for dynamic equipment, pumps, valves, and more.

Trust us to deliver precision, reliability, and innovation in every product we create.

If you require further information or have any inquiries, please feel free to get in touch with us. Our team is here to assist you and provide you with the details you need. We look forward to hearing from you.

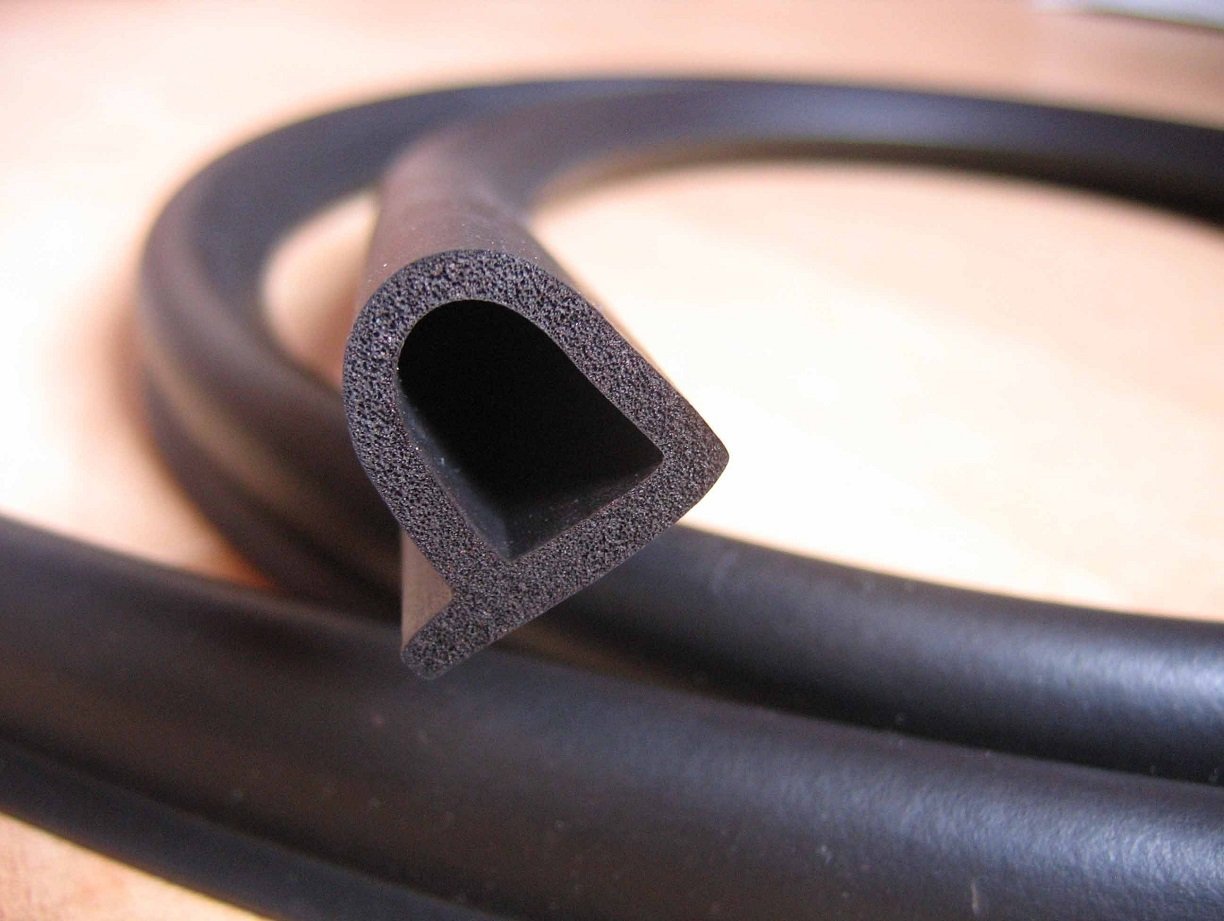

Rubber products

Are made by molding, extruding or cutting rubber plates, depending on the configuration ("O" rings, profiles, sleeves, Simmerring® etc.).

Wide range of rubber products:

SBR, NBR (Nitrile), EPDM, FPM (Viton), MVQ (Silicone);

In the form of: O-ring, Simmerring®, sheet (or cut gasket), round cord.

FEP: PTFE O-ring with Viton or Silicon core for better elasticity.

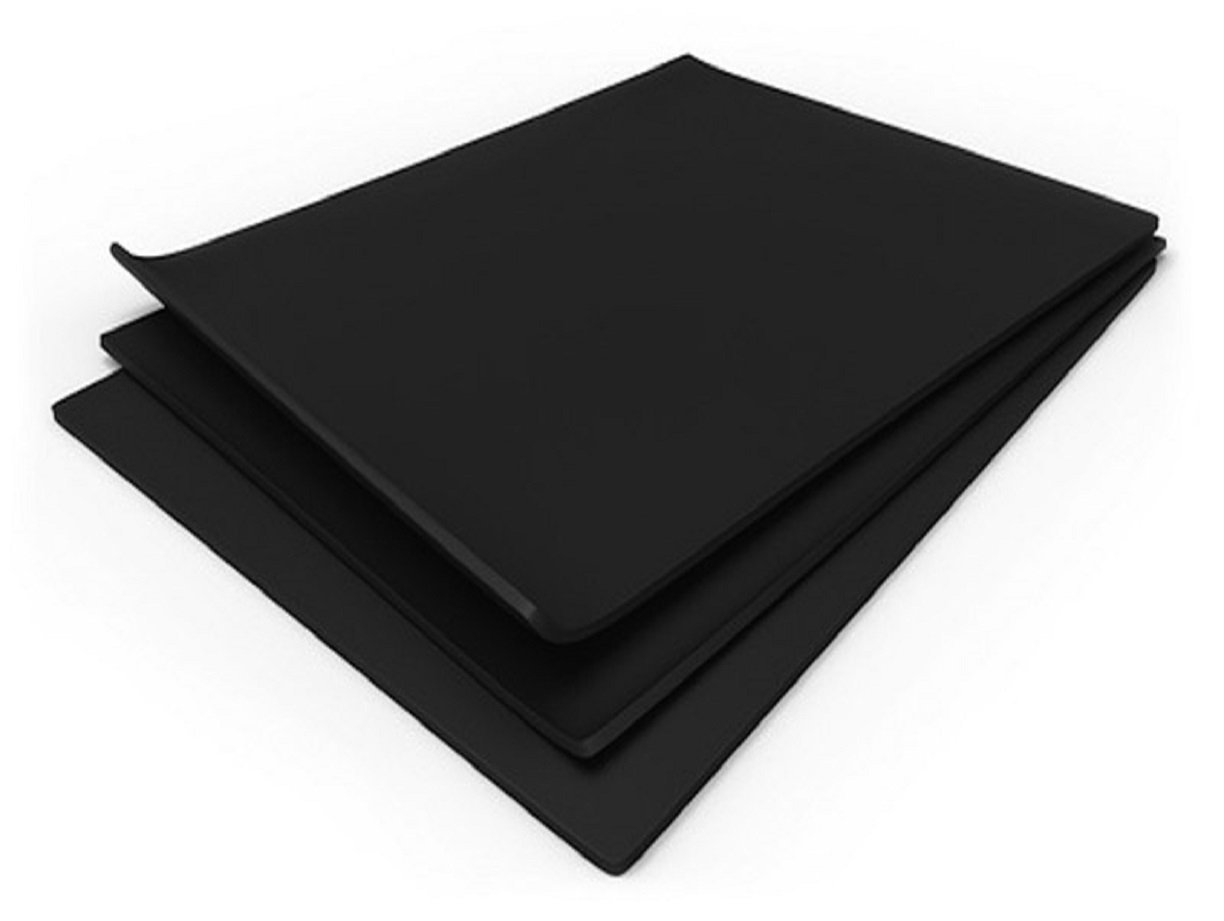

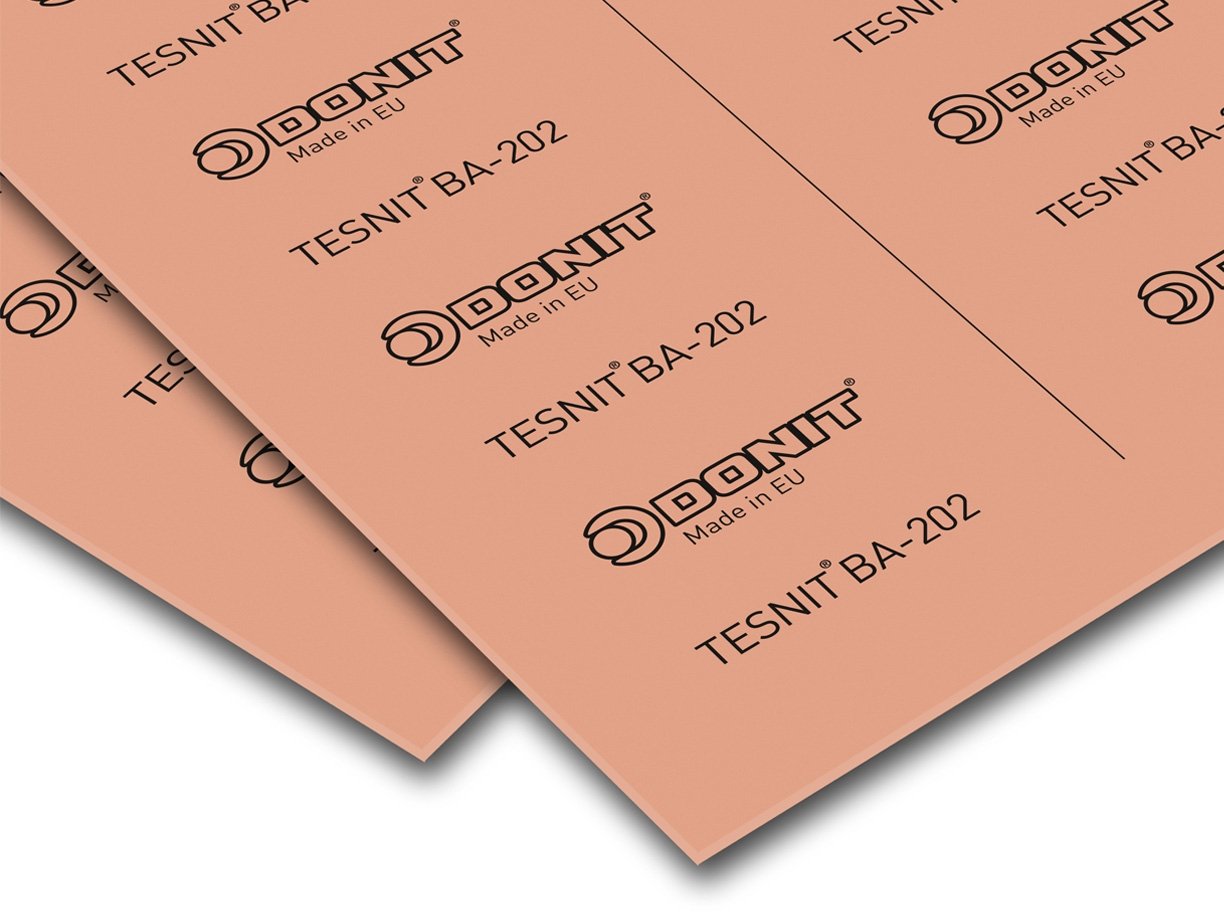

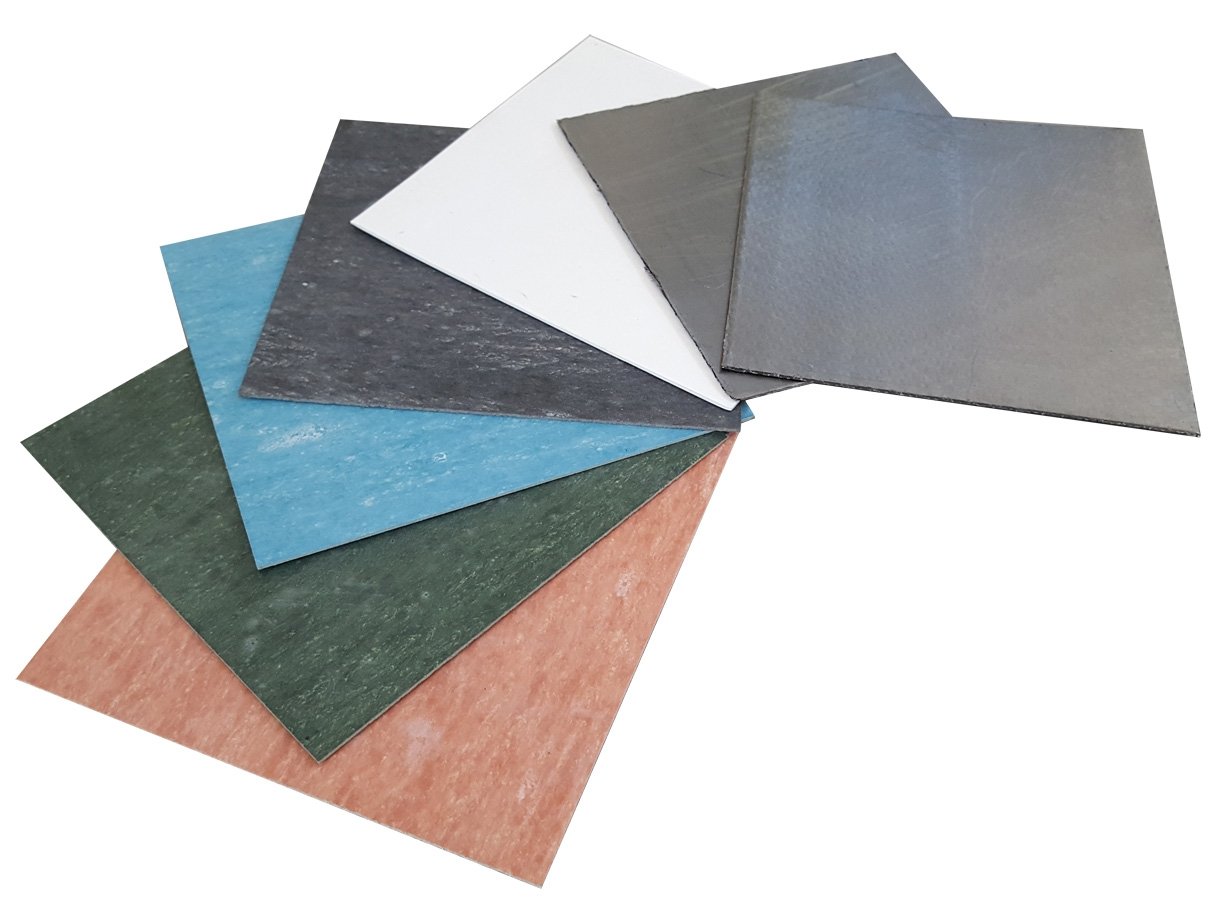

Gasket sheets

Non-asbestos fiber, glass fiber with rubber binder. Temperature resistance between -50 ° C and 250 ° C, pressure of 40 bar, suitable for environments such as: wastewater, hot water, air, chemicals, gases, oils, fuels.

Graphite and aramid fibers with or without metal inserts for better thermal stability, chemical stability and for increased flexibility. Temperature resistance between -50 ° and 350 ° C, pressures up to 100 bar, water, air, chemical products, hydrocarbons, oils etc

High purity graphite with 316L stainless steel or perforated metal insert. Temperature resistance between - 200 °C and 550 °C, 100 bar maximum pressure, recommended for steam, gas, chemicals, hydrocarbons, oils etc.

Expanded / sintered PTFE. Temperature resistance from -200 °C to + 260 °C and 40 bar pressure suitable for aggressive chemical environments, pharmaceutical industry, food industry.

Mica-foil, for high temperature up to 900 °C and maximum pressure of 5 bar, recommended in the petrochemical industry.

Rubber sheets: SBR, NBR, EPDM, MVQ, silicone etc.

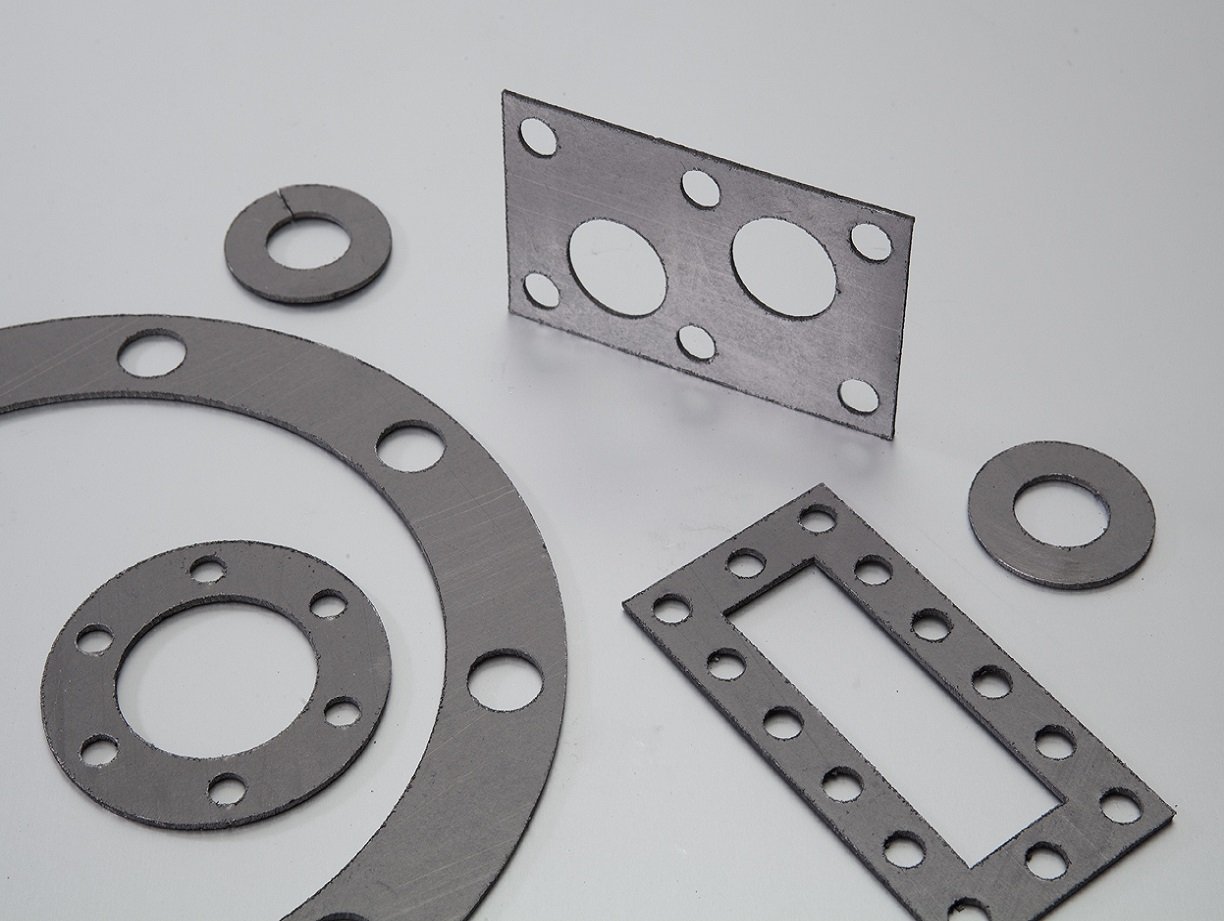

Flat gaskets

We specialized in producing non-asbestos sealing gaskets according to standards (SR EN, DIN, ANSI, JIS) or nonstandard sizes, of any shape or size, according to client drawings and requests.

The offer includes cut gaskets made of materials containing: aramid fibers, glass fibers with rubber binder, graphite, graphite and aramid fibers with or without metal inserts, rubber, PTFE, mica, heat-resistant materials and other materials that are suitable to this type of processing.

Our specialists offer customers assistance in choosing the right material for each application, taking into account all the parameters provided:

- Working fluid and its compatibility with the gasket material;

- Temperature, working pressure and material tolerance to withstand these conditions;

- Torque vales applied on the gasket surface and the capability of the material to withstand these pressures;

- Application workflow (continuously, with temperature and / or pressure variations, intermittently).

We provide our customers detailed information about all materials: technical data sheets, certifications (fire resistance, TA Luft certificates etc.) or approvals of materials used in various applications (oxygen, gas, fuel, drinking water).

The company owns a permanent stock of various materials to ensure deliveries in the shortest possible time.

Braided packings

Suitable for dynamic and static applications (pumps and valves).

Types of packings :

PTFE packing (used for centrifugal pumps, piston pumps, mixers, valves for any industry sector).

Aramid fiber packing (especially used in chemical and petrochemical plants, refineries, thermal plants, in contact with aggressive chemicals, water, solvents, oil derivatives, fats and oils).

Graphite packing (used in chemical and petrochemical plants, in thermal plants and for use with steam, water, gases, oils, process water and chemical solutions, with excellent thermal conductivity).

Carbon packing (water, steam, weak acids, alkali, cellulose, oils, solvents).

Natural fiber packing - cotton (drinking water, food industry, weak acids, water, gas, steam).

Combinations of these fibers (PTFE + aramid, graphite + carbon).

We offer technical assistance for choosing the right solutions based on the information provided by the beneficiary, depending on the following:

The environment (domain - pH, aggregation state)

Temperature (constant, variable)

System status (surfaces, tolerances, modifications)

The pressure (constant, variable)

Working conditions (static, rotary, oscillator)

The company can also offer preformed rings of various sizes and types (sealing packages of complete sets from one material or application-specific combinations).

Heat resistant materials

Thermoresistant materials are designed for thermal insulation or for manufacturing components working in high temperature environments.

We can offer materials made of fiberglass or ceramic fiber in various forms:

Braided packings with rectangular or circular cross-section;

Twisted packings with circular cross section;

Fabrics (tape, tube);

Mats

The maximum temperature for glass fiber based materials is up to 600°C.

The maximum temperature for ceramic fiber materials is up to 1200°C.

Delivery form: materials or finished products (such as rings, gaskets or other types of processed parts).

Various products

1. Protective rings for flange joints, depending on the application, they can be made of:

Polypropylene (working temperature: from -40°C up to + 100°C; DIN EN 1092-1 and ANSI B 16.5 standard)

Stainless steel (1.4571) - (working temperature: from -40°C up to + 400°C; standard DIN EN 1092-1 and ANSI B 16.5)

2. Flange protections:

PTFE - these can be used for a wide variety of chemical products and process fluids, including sulfuric acid, nitric acid, caustic soda, mineral oils. The material is opaque, so in the event of leakage or splashing, the information is provided by a chemical visual indicator that varies depending on the fluid temperature. The working temperature is from -200°C up to + 250°C.

PVC - is an ideal solution for aggressive chemicals in a temperature range from -20°C up to +80°C. In order to see in advance any product faults that occur in the flange connection, they can be equipped with a fully transparent chemical window compatible with this material.

3. Plastics made of polyamide, polyethylene, plexiglass (acrylic glass), polyacetal in the form of semi-finished products (bars, sleeves or sheets).

4. Products from pure PTFE or combined with other materials (graphite, carbon, glass fiber, bronze, molybdenum).

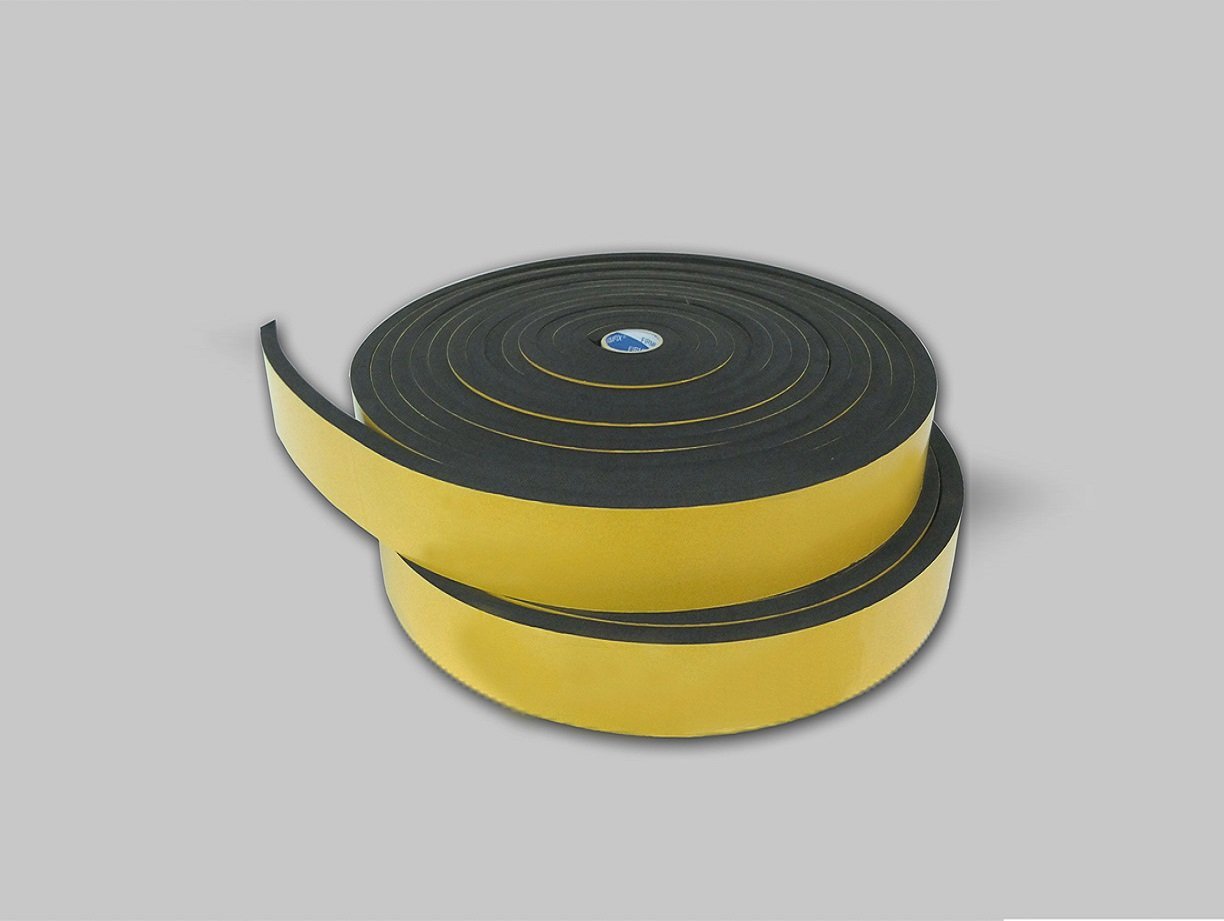

5. Corrugated graphite tape with or without adhesive.

6. Various types of manual cutters for soft gaskets, packing extractors, packing cutters.

7. Compensators and fabrics for compensators.